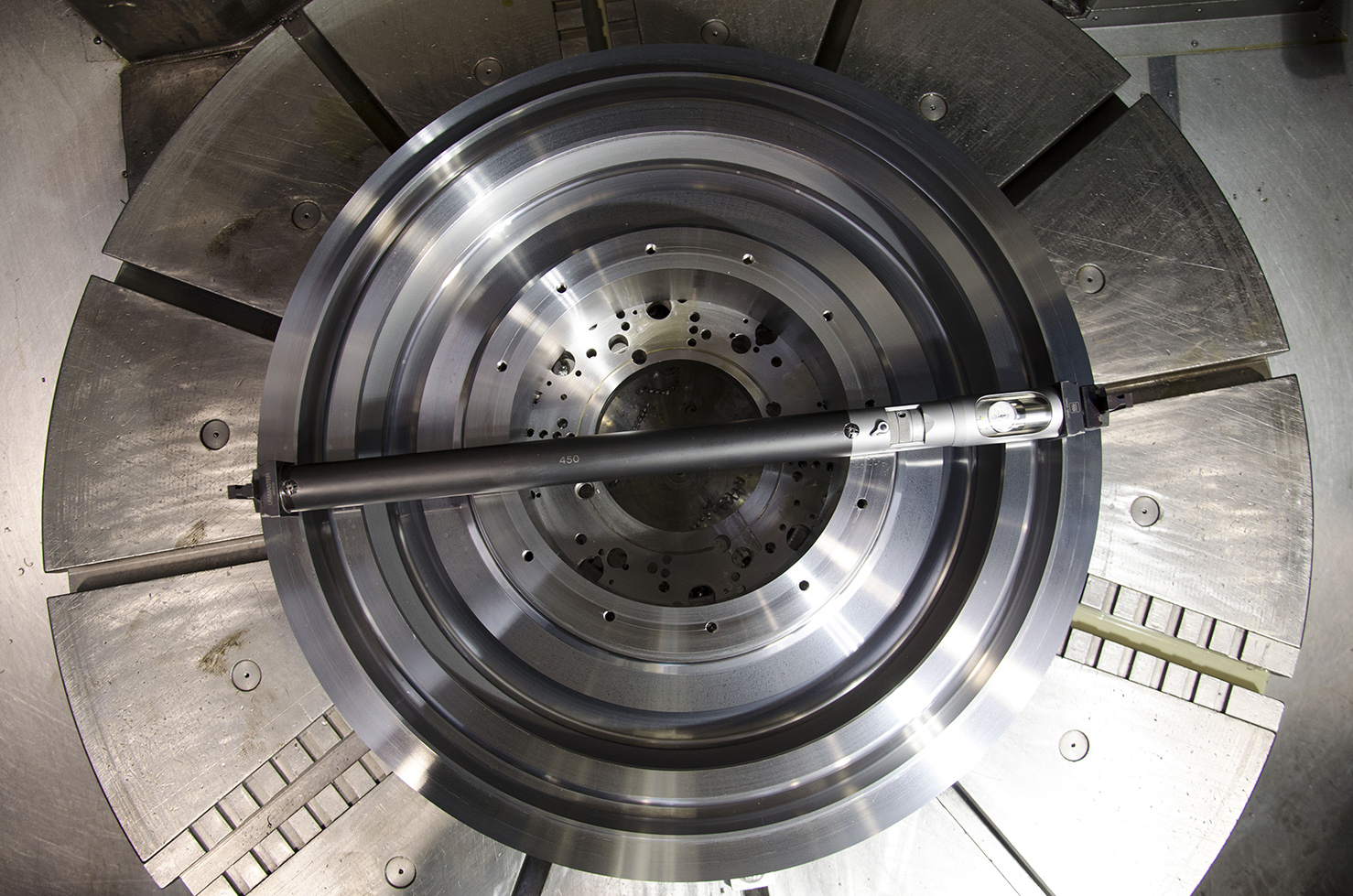

The company specializes in processing high-precision rings for applications in the following sectors:

Production for the petrochemical sector:

For the petrochemical sector, ASZ usually works on behalf of third parties, manufacturing large diameter gaskets for valves or other related components. The range of materials used varies from common steels to highly alloyed special steels, 300 and 400 series stainless steel, duplex and super-duplex and bronze alloys.

ASZ srl provides its customers with complete 360° service thanks to collaboration with external, loyal and certified suppliers; enabling us to supply the raw materials to be processed (cast iron and steel, forged and rolled, flame or plasma cut) precision toothing and grinding, heat treatments such as tempering, induction hardening, nickel plating, nitriding and painting services.

Thanks to our internal processes, we guarantee the traceability of materials and the precision required by drawings. Our production department is equipped with gauges and measuring instruments among the most accurate available on the market, which are checked and calibrated periodically to maintain maximum reliability.

Our metrology lab is equipped with a Zeiss Accura II three-dimensional measuring machine for the checking and certifying of items.